INNOVATION AND TECHNOLOGY

Every brick is an idea, and innovation builds the foundation.

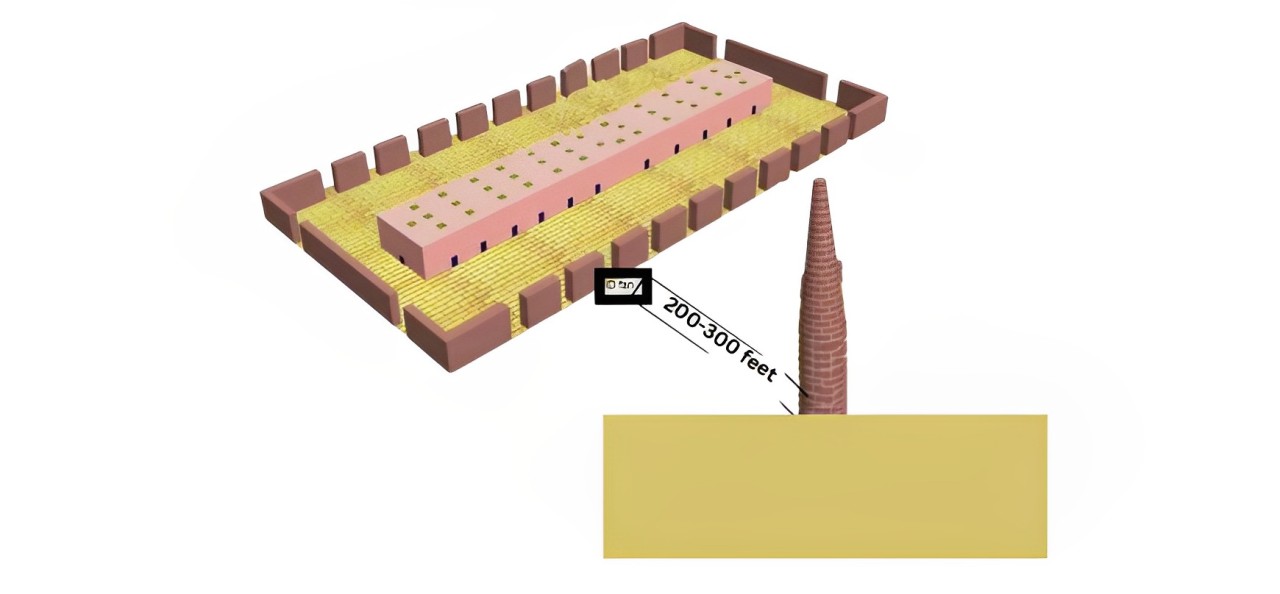

Our innovation centers on the implementation of a modern/improved Zig-Zag technology kiln, a game-changing solution in the brick manufacturing industry. Traditional brick kilns are notorious for their inefficient combustion processes and high emissions of pollutants. However, by adopting modern/improved Zig-Zag kilns, we introduce a revolutionary design that when particulate matter, carbon particles, and flue gases pass through a tunnel 200-300 feet long to stack away from ID fans and brick kilns to allow settling of particulate matter, carbon particles, and fuel gases, potentially reducing stack emissions more than 50% optimizes firing chambers with a zigzag pattern. This innovation significantly improves stack emissions more than 50%, heat distribution, reduces fuel consumption, and results in dramatically lower emissions of harmful pollutants like particulate matter, sulfur dioxide, and carbon monoxide. Not only does this technology enhance the environmental sustainability of brick production, but it also offers substantial economic advantages by lowering energy costs. We complement this innovation with sustainable practices such as brick recycling, exploring alternative building materials, and integrating advanced control systems for real-time monitoring and emission reduction. Our unwavering commitment to these innovative solutions underscores our mission to revolutionize the brick manufacturing industry, reduce its environmental footprint, and pave the way for a cleaner, more sustainable future.

PRODUCT INNOVATION

PRODUCT INNOVATION